-

High-efficiency 20L, 30L, 40L baking planetary mixer

A planetary mixer is an essential piece of equipment for any commercial kitchen or bakery. This versatile machine is designed to mix, whip and blend a variety of ingredients, making it ideal for everything from baking bread and pastries to making soups, sauces and marinades.

-

China high quality baking planetary mixer

A planetary mixer is an essential piece of equipment for any commercial kitchen or bakery. This versatile machine is designed to mix, whip and blend a variety of ingredients, making it ideal for everything from baking bread and pastries to making soups, sauces and marinades.

-

5trays 8trays 10trays 12trays 15trays Convection Oven Hot Air Bakery For Baking

There are 5/8/10/12/15 trays convection oven in the factory,heating by electric or gas. It is for baking pizza,baguette,toast,cookies, biscuit,cake etc.which use radiant heat to cook food, convection ovens use fans to circulate hot air throughout the cooking chamber. This continuous heat cycle allows for even cooking and browning, resulting in perfect dishes every time. From bake to bake, convection ovens simplify the cooking process, reduce cooking time and ensure consistent results

-

64 trays rotary oven electric gas diesel heating double trolley hot air rotary oven for baking

Suitable for biscuits, shortbread, pizza and roast chicken and duck baking

the 64-tray rotary oven with twin trolleys. This oven is designed to meet the demands of high-volume baking operations, delivering efficient, consistent and high-quality results every time.

-

4 trays 8 trays 10 trays trays deck oven electric gas heating layer type oven

The new deck oven, a versatile and efficient baking solution for commercial and residential use. It is an oven commonly used for baking bread, pizza, and other baked goods. Deck ovens are named for the stacked, or tiered, baking surfaces within the oven.

-

15 trays 20 trays 22 trays deck oven electric gas heating for baguette toast pita bread

This deck oven is built with precision and durability in mind, using high-quality materials and expert craftsmanship. It comes with multiple platforms, each with individually controlled temperatures, allowing you to bake different products at the same time without any disruption. The spacious interior provides ample room for high-volume production and is ideal for commercial use in bakeries, pizzerias and restaurants.,also to make the breads, muffins, cake, cookies, pita, dessert, pastry and so on.

-

Biscuit production line manufacturer crisp biscuit production line-L

This production line is suitable for producing both crisp and tough biscuits, with precise temperature control in the baking process to ensure uniform color and stable quality of the final biscuits, and can be customized according to customers’ specific production needs.

Jingyao Fully Automatic Biscuit Production Line integrates multiple functions such as dough mixing, dough rolling, forming, baking, and conveying, realizing a fully automated workflow from raw materials to semi-finished biscuits, which significantly reduces manual intervention and improves production efficiency.

-

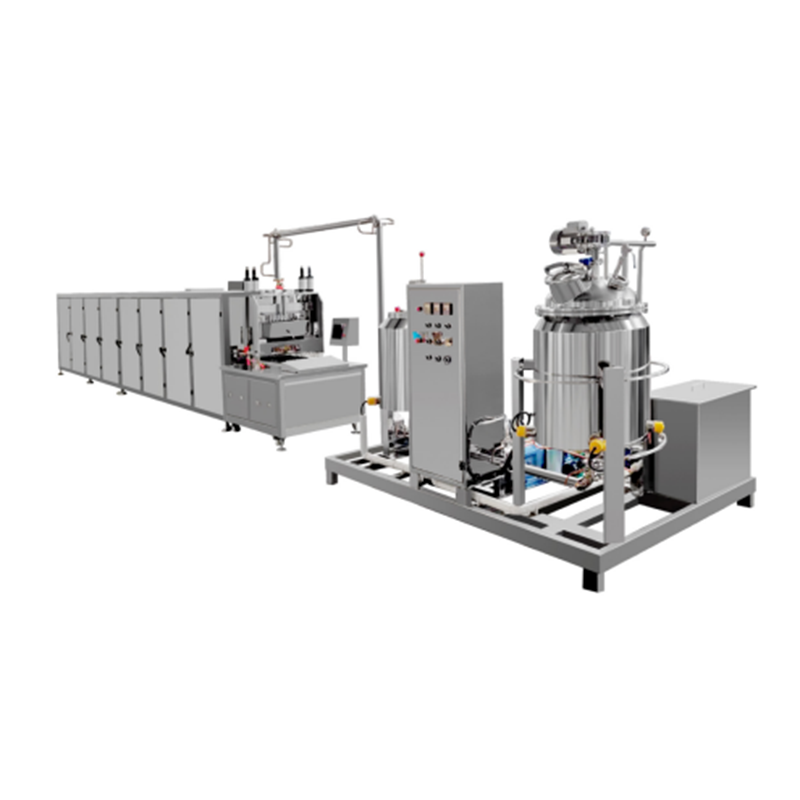

Hard and Soft Candy Making Machine

What kind of candies can we produce with a full automatic candy production line?

Well, the possibilities are endless! With the latest technology and advanced machinery, a full automatic candy production line can produce a wide variety of candies, including double colors candies, single color candies, multicolor candies and different shapes.

The production line is equipped with PLC control to handle candy vacuum cooking, conveying, and depositing procedures. This ensures precise and efficient production, resulting in high-quality candies every time. Additionally, the line is capable of performing rationed filling of essence, pigment, and acid solutions, allowing for the creation of unique and flavorful candies.

One of the standout features of the machine is its automatic stick placing device, which provides good stability and reliability. This ensures that each candy is perfectly formed and ready for packaging. Furthermore, the entire production line is designed with sanitation in mind, featuring a compact structure and reliable performance. This not only ensures the quality and safety of the candies but also makes for easy cleaning and maintenance.

With this level of technology and precision, the production line can create an array of candies, including double colors candies, which feature two distinct colors in a single piece. Single color candies are also easily produced, providing a classic and timeless treat. And for those looking for a more visually striking option, the production line can also produce multicolor candies, featuring a rainbow of hues in each piece.

In conclusion, a full automatic candy production line offers the capability to produce a wide range of candies, from classic single color options to more unique double and multicolor varieties and multi-shapes candies. With its advanced technology and efficient production capabilities, the possibilities for candy creation are virtually limitless. So, whether you’re craving a traditional treat or a more innovative confection, rest assured that a full automatic candy production line has you covered.

-

Full Automatic 600kg/h Candy Production Line

What kind of candies can we produce with a full automatic candy production line?

Well, the possibilities are endless! With the latest technology and advanced machinery, a full automatic candy production line can produce a wide variety of candies, including double colors candies, single color candies, multicolor candies and different shapes.

The production line is equipped with PLC control to handle candy vacuum cooking, conveying, and depositing procedures. This ensures precise and efficient production, resulting in high-quality candies every time. Additionally, the line is capable of performing rationed filling of essence, pigment, and acid solutions, allowing for the creation of unique and flavorful candies.

One of the standout features of the machine is its automatic stick placing device, which provides good stability and reliability. This ensures that each candy is perfectly formed and ready for packaging. Furthermore, the entire production line is designed with sanitation in mind, featuring a compact structure and reliable performance. This not only ensures the quality and safety of the candies but also makes for easy cleaning and maintenance.

With this level of technology and precision, the production line can create an array of candies, including double colors candies, which feature two distinct colors in a single piece. Single color candies are also easily produced, providing a classic and timeless treat. And for those looking for a more visually striking option, the production line can also produce multicolor candies, featuring a rainbow of hues in each piece.

In conclusion, a full automatic candy production line offers the capability to produce a wide range of candies, from classic single color options to more unique double and multicolor varieties and multi-shapes candies. With its advanced technology and efficient production capabilities, the possibilities for candy creation are virtually limitless. So, whether you’re craving a traditional treat or a more innovative confection, rest assured that a full automatic candy production line has you covered.

-

High Capacity Candy Production Line

What kind of candies can we produce with a full automatic candy production line?

Well, the possibilities are endless! With the latest technology and advanced machinery, a full automatic candy production line can produce a wide variety of candies, including double colors candies, single color candies, multicolor candies and different shapes.

The production line is equipped with PLC control to handle candy vacuum cooking, conveying, and depositing procedures. This ensures precise and efficient production, resulting in high-quality candies every time. Additionally, the line is capable of performing rationed filling of essence, pigment, and acid solutions, allowing for the creation of unique and flavorful candies.

One of the standout features of the machine is its automatic stick placing device, which provides good stability and reliability. This ensures that each candy is perfectly formed and ready for packaging. Furthermore, the entire production line is designed with sanitation in mind, featuring a compact structure and reliable performance. This not only ensures the quality and safety of the candies but also makes for easy cleaning and maintenance.

With this level of technology and precision, the production line can create an array of candies, including double colors candies, which feature two distinct colors in a single piece. Single color candies are also easily produced, providing a classic and timeless treat. And for those looking for a more visually striking option, the production line can also produce multicolor candies, featuring a rainbow of hues in each piece.

In conclusion, a full automatic candy production line offers the capability to produce a wide range of candies, from classic single color options to more unique double and multicolor varieties and multi-shapes candies. With its advanced technology and efficient production capabilities, the possibilities for candy creation are virtually limitless. So, whether you’re craving a traditional treat or a more innovative confection, rest assured that a full automatic candy production line has you covered.

-

Stainless Steel Galvanized Sheet Aluminum New Single Axle Mobile Food Truck

BT series is an air stream model with outstanding outlook.This Single Axle Mobile Food Truck have 2.7M,2.8M,3M,etc.,The standard outside material is mirror stainless steel.If you don’t want it so shining,we could make it aluminum or paint it with other colors.It can also be customized to your needs. -

5-10 Ton Commercial Large Block Ice Machine for Sale

Block ice machine refers to a machine designed to produce large blocks of ice. Such machines are often used for commercial and industrial purposes, such as in the fishing, food processing and beverage industries. The block ice machine can produce large blocks of ice to supply cold chain transportation, storage and cooling needs. These machines typically use a condenser and compressor to condense and freeze water, forming solid ice.

Shanghai Jingyao ice machine has an intelligent operating system, which is simple and easy to use. Through the control buttons on the operation panel, users can easily set parameters such as ice making time, ice making mode, and ice cube size. The equipment is also equipped with a safety protection system that can monitor the operating status of the equipment and automatically stop working to ensure safe use.