High-Efficiency Automatic Candy Machine Production Line

Application

Suitable for producing various candy types, including hard candies, soft candies, gummy bears, lollipops, and filled candies, meeting diverse market needs.

Adapts to small-batch trial production and large-scale mass production, with adjustable output (150-600kg/h) to match business scales.

Enables quick switch between different candy styles by replacing molds, saving time on production line reconfiguration.

Ideal for candy manufacturers looking to reduce manual labor and improve production efficiency without compromising quality.

Features

Integrates key automatic functions: automatic raw material mixing, precise temperature control for cooking, and automatic cooling to ensure consistent candy texture.

Uses PLC control system with a simple touchscreen interface, allowing operators to set parameters, store recipes, and monitor production status in real time.

Features food-grade stainless steel parts for all contact surfaces, making cleaning easy and complying with global food safety standards (e.g., GMP, HACCP).

Includes an automatic packaging unit that seals candies individually or in batches, preventing moisture and extending shelf life.

Automation & Technical Advantages

Widely used in food processing plants, snack brands, and custom candy workshops, supporting both standard and personalized candy production (e.g., branded shapes, flavor combinations).

Reduces raw material waste with precise dosage control during mixing and molding, lowering overall production costs for businesses.

Compatible with different power supplies (110V/220V/380V) and adjustable line length, fitting various factory spaces and regional electrical requirements.

Supports long-term continuous operation with durable components, minimizing downtime for maintenance and ensuring stable daily production output.

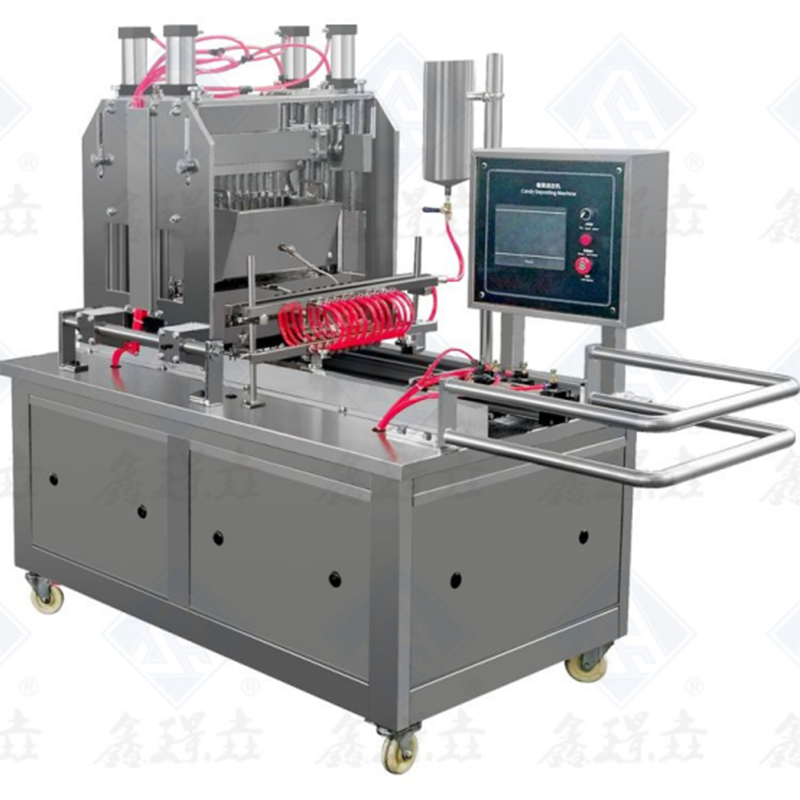

Detail Display