Y High-Efficiency Full Automatic Cake Production Line

Product Description

1.Our fully automated cake production line has been developed by drawing on advanced European equipment technology while integrating the actual conditions of individual production workshops. This all-in-one system combines electrical, optical, and mechanical technologies into a seamless operation.

2.The system comprises five main components: batter preparation, baking unit, filling mechanism, cooling system, and sterilization module. (Additionally, the components can be configured into semi-automatic setups or high-capacity production lines.) Various tunnel oven options are available, including electric, diesel, gas, and thermal oil models.

Automation & Technical Advantages

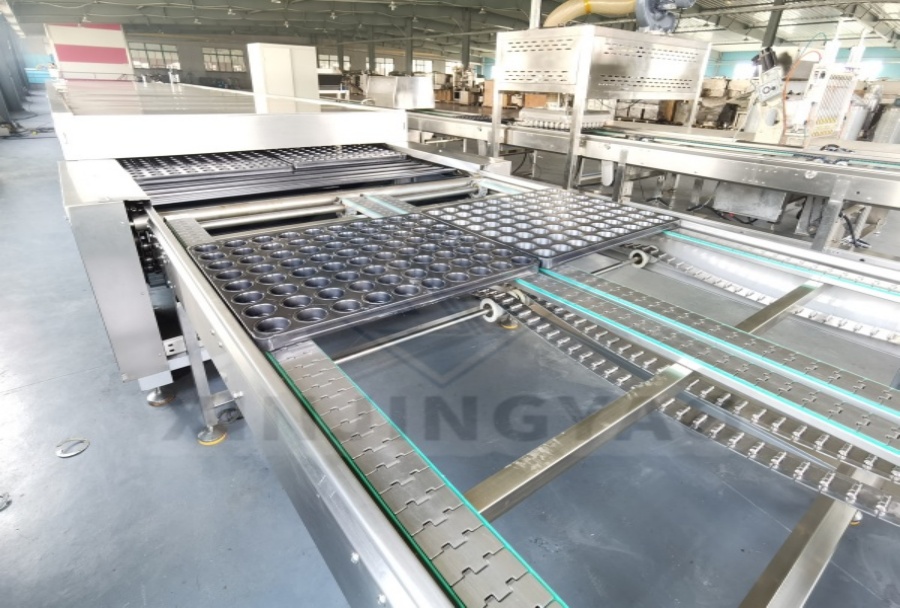

1.This multifunctional production line manages the entire manufacturing process from batter preparation through to final packaging, encompassing forming, extrusion, baking, filling, rolling, cutting, and sterilization stages.

2.It demonstrates exceptional versatility in producing different cake varieties: by changing molds, it can create stuffed egg yolk pastries, paper cup cakes, and sliced cakes in various configurations.

3.This system is particularly suitable for medium to large food factories, bakeries, and snack processing companies that require standardized, high-efficiency production.

Features

1.Operated via a computerized frequency conversion control system, the line allows for precise parameter adjustments with intuitive operation.

2.The tunnel oven features six temperature zones (front, middle, rear, upper, and lower) with hot air circulation, controlled by proportional motors and butterfly valves to ensure uniform heating – resulting in cakes with a soft texture and consistently golden appearance.

3.Compared to traditional equipment, its energy-efficient design reduces power consumption by up to 30% during regular operation. Furthermore, reduced manual product contact combined with the sterilization module extends shelf life while complying with food safety regulations.

4.Supported by customizable solutions and dependable after-sales service, this system has earned extensive recognition in the bakery equipment marketplace.

Advantage

Fast, even mixing of ingredients; consistent slurry texture. * Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste. * Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean. * Touch screen: Easy operation, precise control; stores recipes for versatility. * Labor-saving: Single-operator use; streamlined mixing-to-feeding process.

Detail Display

.jpg)

.jpg)