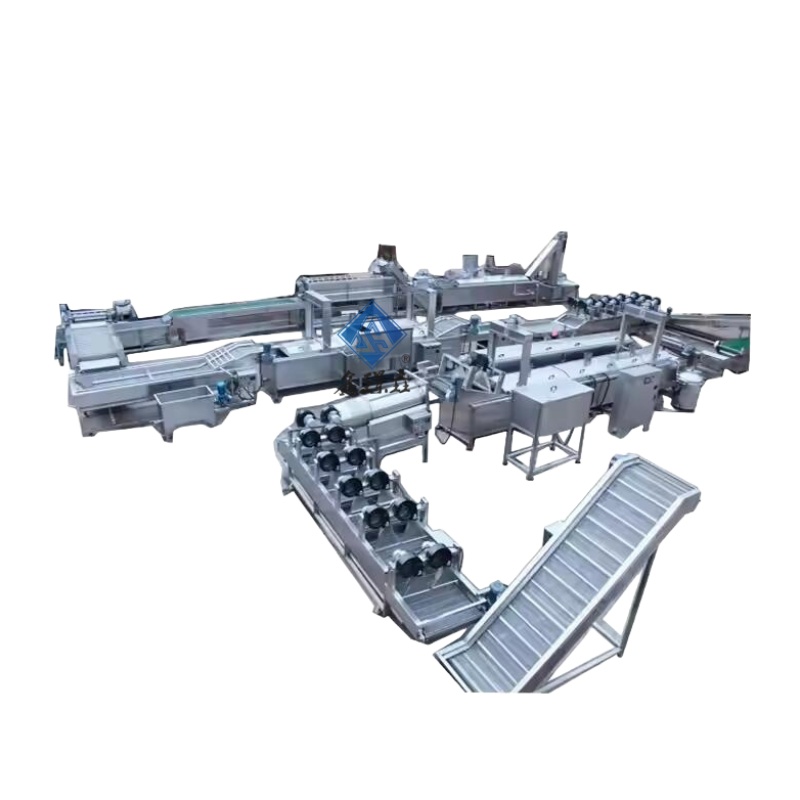

Potato Slicer For Chips Production Line-A XINJINGYAO

Ⅰ.Overall Energy Consumption and Configuration

◈Power Consumption: 160KW (total power), installation power 125KW

◈Oil Consumption: 25kg/h (for frying); Fuel consumption: 25-30m³/h (for relevant equipment)

◈Compressed Air: Pressure 6kgs/cm², airflow rate 1.2 m³/minute

◈Personnel Allocation: 3-4 engineers required for installation, 8-10 workers required for daily production

Frying Machine Specification: Length 9.6M, using palm oil for frying

Overall Energy Consumption and Configuration

| Equipment Name | Quantity | Main Parameters |

|---|---|---|

| Cone Mixer | 1 set | Main material: SS304; Power: 4KW; Weight: 300Kg; Mixing Speed: 62RPM; Capacity: 0.3M³; Size: Ø1000×2000MM |

| Flour Mixer | 1 set | Transmission Power: 11KW (spindle speed controlled by frequency conversion, 25-30HZ); Weight: 2000kg; Size: 1100×550×1050mm; Parts in contact with food are made of stainless steel |

| Frying Machine | 1 set | Power: 16.2KW; Main material: Stainless Steel; Weight: 5000Kg; Size (L×W×H): 9700×2100×2300MM; Oil Capacity: 1400Kg; Effective Frying Length: 9M; Oil Consumption Amount: 30-33% |

| Automatic Weighing and Packing Machine | 2 sets | Model: JY-250; Packing Speed: 30~70 Packages/Minute; Packing Weight: 100~1000G/Package; Drive Motor: 3.00KW; Applicable Wrapping Materials: Cellophane, PVC, Polypropylene, waxed paper, PET, CPP, BOPP+CPP, compound material, etc.; Net Weight per set: 1500KG; Size (L×W×H): 4000×3000×3200MM |

Core Parameters of the Equipment

Overall Energy Consumption and Configuration

⑴Power Consumption: 160KW (total power), installation power 125KW

⑵Oil Consumption: 25kg/h (for frying); Fuel consumption: 25-30m³/h (for relevant equipment)

⑶Compressed Air: Pressure 6kgs/cm², airflow rate 1.2 m³/minute

⑷Personnel Allocation: 3-4 engineers required for installation, 8-10 workers required for daily production

⑸Frying Machine Specification: Length 9.6M, using palm oil for frying

Production Process

The JY-250 Compound Potato Chips Production Line follows a standardized processing process, with full automation from raw material processing to finished product packaging, ensuring stable quality of potato chips and efficient production. The specific process is as follows:

⑴Raw Material Lifting and Mixing: Raw materials are transported to the V-type mixer by the raw material hoister, and the cone mixer and flour mixer are used to achieve uniform mixing of raw materials.

⑵Dosing and Sheeting: The ration powder feeder accurately controls the amount of raw materials. The mixed raw materials are pressed into thin sheets of specified thickness (0.8mm) through the pre-sheeting machine and sheeting machine.

⑶Forming and Processing: The forming machine processes the thin sheets into potato chip shapes of 66×46mm. The leftover materials are crushed by the back-to-material crushing machine and sent back for reuse by the back material conveyor.

⑷Frying and Cooling: The potato chips enter the frying machine (with palm oil) for frying, and then are cooled by the cooling conveyor to ensure a crispy taste.

⑸Flavoring and Packaging: The flavoring system (roller seasoning machine, spray seasoning machine) adds flavor to the potato chips, and finally the automatic weighing and packing machine completes the packaging to form the finished product.

Services and Guarantees

⒈Installation and Debugging: The seller is responsible for the installation and commissioning of the equipment, and bears the labor cost of engineers (40USD/Day/Person) and personal insurance. The buyer shall bear the costs of the engineers' round-trip air tickets, accommodation, local transportation, etc., and provide common tools required for installation and debugging; the seller shall be responsible for special tools if needed.

⒉Personnel Training: During and after the installation and commissioning period, the seller's engineers will provide training to operators and maintainers to ensure that they can skillfully operate the equipment and master maintenance skills.

Quality Guarantee

Spare Parts Supply

Quality Acceptance and Claims

Dispute Resolution