-

L-Block Ice Machine reduces procurement costs + saves electricity bills + requires less maintenance

Block ice machines have emerged as a practical and cost-efficient choice for ice production, addressing the unique needs of different user groups with three key advantages that balance affordability, energy savings, and operational stability.

For small and medium-sized enterprises (SMEs) or first-time investors, block ice machines significantly reduce the pressure of equipment procurement and cut down on capital investment. Unlike high-cost industrial-grade ice-making equipment that requires a large upfront budget, these machines are designed with a cost-friendly pricing strategy while maintaining basic performance standards. They come in a variety of entry-level models that match the initial ice demand of SMEs—for example, a 500kg/day block ice machine can fully meet the needs of a local seafood store or a small-scale catering business, without forcing users to overspend on unnecessary high-capacity functions. This low-threshold investment not only eases the financial burden on new businesses but also allows them to allocate funds to other core operations, such as product promotion or staff training, laying a solid foundation for long-term development.In large-scale ice-making scenarios like aquatic product processing and cold chain warehousing, block ice machines stand out for their ability to significantly reduce electricity costs and expand profit margins. These scenarios require continuous and large-volume ice supply, and traditional ice machines often consume excessive electricity due to inefficient refrigeration systems. Block ice machines, however, adopt advanced energy-saving technologies: their optimized compressor design reduces power consumption by 15%-20% compared to conventional models, and the intelligent temperature control system adjusts the refrigeration intensity according to real-time ice demand, avoiding energy waste caused by constant high-power operation. For a large aquatic processing plant that operates 24 hours a day, this energy-saving feature can save thousands of dollars in electricity bills annually, directly increasing the company’s profit space while reducing its carbon footprint.Moreover, block ice machines minimize maintenance workload by eliminating the need for frequent coolant replacement, and they maintain high-efficiency refrigeration even in low-temperature environments, making them ideal for quick-freezing and cold storage scenarios. Traditional ice machines often require regular coolant replacement to ensure refrigeration efficiency, which not only adds to maintenance costs but also disrupts daily operations. Block ice machines use high-stability refrigeration circuits that allow the coolant to maintain performance for an extended period—usually, coolant replacement is only needed once every 2-3 years, greatly reducing the time and labor spent on maintenance. Additionally, their special insulation and refrigeration components enable them to operate efficiently in low-temperature environments (as low as -20°C). In quick-freezing workshops for meat or seafood, the machines can rapidly produce large block ice to maintain the ultra-low temperature required for food preservation, ensuring the quality of frozen products while avoiding downtime due to poor adaptability to low temperatures. -

L -tube ice machine Global power supply compatibility + High flexibility in various scenarios + EU standards, durable, easy to clean and more convenient to use

Tube ice machines have become a highly sought – after choice in the global ice – making market, thanks to their four outstanding advantages that perfectly cater to the diverse needs of businesses across industries.

First of all, these machines are designed to meet the electrical standards of different regions and support personalized brand promotion, boasting a wide range of applications. Whether it is in regions with 110V power supply in North America, 220V in Asia, or 230V in Europe, tube ice machines can directly adapt without the need for additional voltage conversion devices, saving businesses the trouble of equipment modification and potential operational risks. Moreover, the exterior of the machines offers ample room for personalized brand customization. Businesses can print their logos, brand colors, or promotional slogans on the machine bodies, turning the tube ice machines into mobile brand displays. This not only enhances brand visibility in scenarios like shopping malls, hotels, and beverage stores but also helps businesses leave a deep impression on consumers, expanding their brand influence in local markets.Secondly, tube ice machines feature high flexibility, as they can adapt to different usage scenarios and needs. For instance, in beverage shops that require small – diameter tube ice to keep drinks cool without diluting the taste, the machines can be adjusted to produce ice tubes of 15mm – 20mm in diameter. In seafood markets or catering events that need larger – size tube ice for long – term refrigeration, the machines can switch to producing 25mm – 30mm diameter ice tubes. Additionally, they come in various models, from compact desktop versions suitable for small convenience stores to large – capacity industrial models for factories and logistics centers. This flexibility allows tube ice machines to meet the ice – making needs of businesses of all sizes and types.Thirdly, tube ice machines are sturdy, durable, easy to clean, and have a long service life. The main components of the machines, such as the ice – making cylinder and the refrigeration system, are made of high – quality stainless steel. This material not only has strong corrosion resistance, preventing rust and damage caused by long – term contact with water and ice but also can withstand frequent use in high – intensity environments. When it comes to cleaning, the smooth inner wall of the ice – making cylinder and the detachable parts make the cleaning process simple and efficient. Staff only need to use a soft brush and neutral detergent to clean the machine thoroughly, reducing the time and labor cost of maintenance. With proper use and regular maintenance, a tube ice machine can operate stably for more than 8 years, bringing long – term value to businesses.Last but not least, tube ice machines comply with European Union (EU) standards, which significantly enhances their market competitiveness. EU standards have strict requirements for product safety, energy efficiency, and environmental protection. Tube ice machines that meet these standards not only ensure the safety of ice products (avoiding potential health risks caused by unqualified materials) but also have excellent energy – saving performance, reducing energy consumption during operation. For businesses that intend to enter the European market or expand their business globally, having a tube ice machine that meets EU standards means they can bypass many trade barriers, gain the trust of local consumers more easily, and stand out in the fierce market competition. -

flake Ice Making machine bussiness L-XINJINGYAO

1. It complies with global electricity standards, does not require additional voltage conversion equipment, and has no geographical restrictions on usage.

2. The ice production rate per unit time is higher than that of most similar products, enabling it to quickly meet large-scale ice demand.

3. Precise control of ice sheet thickness, compared to other ice makers, the ice body is uniform and less prone to breakage, resulting in better preservation and refrigeration effects.

4. The noise level is lower than the industry average, and the operation is quiet without disturbing the environment.

5. The installation process is simple, no professional skills or complex tools are required, saving manpower and time costs. -

cube ice maker and cube ice maker-L-XINJINGYAO

This cube ice machine has a wide application range, meeting electricity needs in different regions and personalized brand promotion requirements. It adapts to multiple scenarios with high flexibility, is durable, easy to clean and has a long service life. Complying with EU standards, it effectively enhances market competitiveness.

-

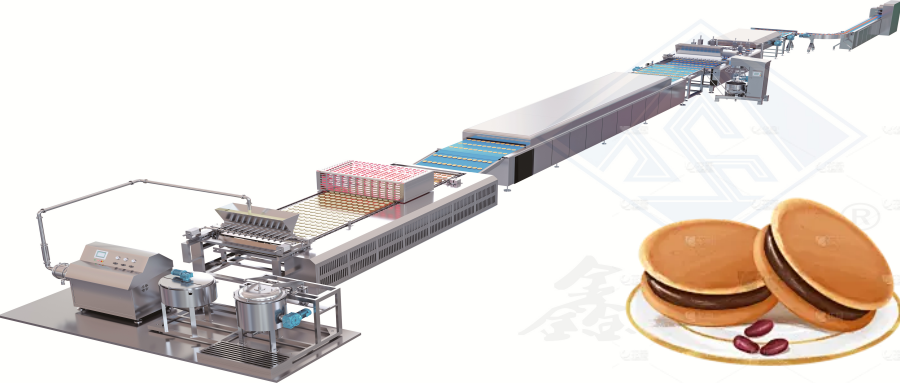

K-XINJINGYAO Commercial Dorayaki Maker Machine Automatic Whole Production Line Dorayaki Machine

XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

Model JY-TLS600

JY-TLS800 JY-TLS1000 JY-TLS1200 Yield(per/hour) 2500 3400 4200 5000 Power(kw) 32.5 35.5 38.5 41.5 Dimenson(mm) 3400*1840*1500 3400*2060*1500 3400*2280*1500 3400*2500*1500 Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.OVEN TUNNEL1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.Company IntroductionShanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.F&Q1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial 2500-8000pieces per hour Dorayaki Production Machine Souffle Dorayaki Machine Automatic Whole Line Dorayaki Equipment

XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

Model JY-TLS600 JY-TLS800 JY-TLS1000 JY-TLS1200 Yield(per/hour) 2500 3400 4200 5000 Power(kw) 32.5 35.5 38.5 41.5 Dimenson(mm) 3400*1840*1500 3400*2060*1500 3400*2280*1500 3400*2500*1500 Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

- Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.- FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.- OVEN TUNNEL

1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.- Company Introduction

Shanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.- F&Q

1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial 2500-8000 pieces per hour Dorayaki Baking Machine Automatic Whole-Production-Line Dorayaki Maker Machine

K-XINJINGYAO Commercial 2500-8000 pieces per hour Dorayaki Baking Machine Automatic Whole-Production-Line Dorayaki Maker Machine

Model JY-TLS600 JY-TLS800 JY-TLS1000 JY-TLS1200 Yield(per/hour) 2500 3400 4200 5000 Power(kw) 32.5 35.5 38.5 41.5 Dimenson(mm) 3400*1840*1500 3400*2060*1500 3400*2280*1500 3400*2500*1500 Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

- Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.- FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.- OVEN TUNNEL

1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.- Company Introduction

Shanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.- F&Q

1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial 2500-8000pieces per hour Automatic Dorayaki Production Machine Japanese-Style Dorayaki Machine Whole-Line Dorayaki Equipment

Model JY-TLS600 JY-TLS800 JY-TLS1000 JY-TLS1200 Yield(per/hour) 2500 3400 4200 5000 Power(kw) 32.5 35.5 38.5 41.5 Dimenson(mm) 3400*1840*1500 3400*2060*1500 3400*2280*1500 3400*2500*1500 Our automatic dorayaki cake production line is a high-efficiency solution tailored for commercial dorayaki manufacturing, addressing pain points of traditional manual production (low efficiency, inconsistent quality, high labor costs). Unlike small-scale manual equipment, this line realizes full-process automation: from raw material mixing to final packaging, each link is controlled by computer programming, ensuring stable product quality and high production efficiency.

- Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.- FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.- OVEN TUNNEL

1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.- Company Introduction

Shanghai Jingyao Industrial Co., Ltd. is located at Shanghai, China. As a professional manufacturer of refrigeration equipment with over 30 years of experience, we also specialize in developing commercial automatic dorayaki cake production lines. This line integrates computer programming control, automatic oil wiping, batter depositing, gas heating baking, precise filling, and packaging, with a production capacity of 2500-5000pcs/h. Backed by our independent R&D department, professional manufacturing base, strict quality control, and excellent after-sales service, it’s ideal for food factories and large-scale bakeries globally.- F&Q

1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

W-XINJINGYAO Commercial 2500-8000pieces per hour Automatic dutch pancake machine commercial Japanese-Style Dorayaki Machine Whole-Line Dorayaki Equipment

Model JY-TLS600 JY-TLS800 JY-TLS1000 JY-TLS1200 Yield(per/hour) 2500 3400 4200 5000 Power(kw) 32.5 35.5 38.5 41.5 Dimenson(mm) 3400*1840*1500 3400*2060*1500 3400*2280*1500 3400*2500*1500 Our automatic dorayaki cake production line is a high-efficiency solution tailored for commercial dorayaki manufacturing, addressing pain points of traditional manual production (low efficiency, inconsistent quality, high labor costs). Unlike small-scale manual equipment, this line realizes full-process automation: from raw material mixing to final packaging, each link is controlled by computer programming, ensuring stable product quality and high production efficiency.

- Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.- FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.- OVEN TUNNEL

1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.- Company Introduction

Shanghai Jingyao Industrial Co., Ltd. is located at Shanghai, China. As a professional manufacturer of refrigeration equipment with over 30 years of experience, we also specialize in developing commercial automatic dorayaki cake production lines. This line integrates computer programming control, automatic oil wiping, batter depositing, gas heating baking, precise filling, and packaging, with a production capacity of 2500-5000pcs/h. Backed by our independent R&D department, professional manufacturing base, strict quality control, and excellent after-sales service, it’s ideal for food factories and large-scale bakeries globally.- F&Q

1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.OVEN TUNNEL1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.Company IntroductionShanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.F&Q1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial Pancake Maker Machine Souffle scallion pancake machine Automatic Whole Production Line Pancake Machine

XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

* Turbine impeller: Fast, even mixing of ingredients; consistent slurry texture.

* Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste.

* Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean.

* Touch screen: Easy operation, precise control; stores recipes for versatility.

* Labor-saving: Single-operator use; streamlined mixing-to-feeding process.FILLING SYSTEM

Consistent batter depositing ensures quality of baked goods. A high-efficiency cake batter depositor handles batters quickly and precisely.Key Features:- Compatible with various batters like sponge cake, chiffon cake, etc.- Made of food-grade stainless steel and aluminum, durable and easy to clean.- Has intelligent control system with LCD touch screen and PLC.- Servo motor enables precise depositing. – Anti-foaming design ensures stable product quality.- Customizable compartments

meet customer needs.OVEN TUNNEL1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.Company IntroductionShanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.F&Q1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair. -

K-XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine automatic-pancake-machine Whole Production Line Machine

XINJINGYAO Commercial Pancake Maker Machine Souffle Pancake Machine Automatic Whole Production Line Pancake Machine

Our full automatic cake production line is research and developed on the basis of Europe’s advanced equipment, and colligate with the real condition of individual workshop. The full automatic cake line is gather the electricity, light and machine together. With the merits of high automation, large capacity, fewer workers, and fewer workers touched with the product, long quality guarantee period etc., it is very popular by food factories. The equipment is divided into five parts: the batter mixing, baking oven, filling, cooling & sterilization, packaging. (Additional, the equipments can be combined into a semi-automatic, large-volume production line.) you can choose different types of tunnel oven (such as Electricity, Diesel, Gas, Thermal oil).

Product Details

MIXING AND AERATORING SYSTEM Advanced, efficient cake mixer for modern baking:

A cutting-edge, high-efficiency cake mixer tailored for contemporary baking operations, designed to streamline ingredient processing while ensuring consistent quality:

- **Turbine Impeller**: Delivers rapid, uniform mixing of raw materials, eliminating lumps and guaranteeing a smooth, homogeneous slurry texture—critical for stable cake structure.

- **Mace Air Infusion Technology**: Enables efficient air incorporation into the batter, supporting reliable rising during baking. This results in a delicate, fluffy crumb and rich, well-balanced flavor in the final product.

- **Food-Grade Stainless Steel Construction**: Meets global food safety standards (e.g., FDA, EU 10/2011), offering exceptional durability, resistance to corrosion from acidic ingredients (like milk or fruit puree), and hassle-free cleaning to reduce downtime.

- **Intuitive Touch Screen Interface**: Simplifies operation with clear, graphical controls for mixing speed, time, and aeration levels. It also stores up to 50 custom recipes, allowing quick switching between products (e.g., sponge cake, pound cake) for versatile production.

- **Labor Optimization**: Designed for single-person operation, with a seamless workflow from mixing to batter transfer—cuts manual labor by 30% compared to traditional mixers and minimizes ingredient waste.FILLING SYSTEM

This system ensures precise, consistent batter depositing— a key factor in maintaining uniform quality across every baked good. Its high-performance cake batter depositor handles various batter viscosities quickly and accurately, adapting to diverse production needs:

- **Wide Batter Compatibility**: Works seamlessly with different batter types, including sponge cake, chiffon cake, and even dense cake batters (e.g., red velvet), no need for complex adjustments.

- **Food-Safe Materials**: Crafted from food-grade stainless steel (for contact parts) and lightweight, corrosion-resistant aluminum (for non-contact components), ensuring easy sanitization and long-term use in high-humidity bakery environments.

- **Intelligent Control Setup**: Equipped with an LCD touch screen and PLC (Programmable Logic Controller) for precise parameter adjustment (e.g., deposit volume, speed). The PLC also enables synchronization with upstream mixers and downstream ovens for automated production.

- **Servo Motor-Driven Precision**: Uses a high-torque servo motor to control depositing accuracy within ±2g, avoiding over-depositing (wasting batter) or under-depositing (small, uneven cakes).

- **Anti-Foaming Design**: Features a special flow channel that reduces air bubble formation during depositing—prevents “hollow” or “cracked” cakes caused by excess bubbles in the batter.

- **Customizable Compartments**: Offers modular compartment options (e.g., 2, 4, or 6-nozzle setups) to match production scales, from small-batch artisanal cakes to large-volume commercial runs.OVEN TUNNEL1. Energy-Efficient Design: Ceramic insulation cuts energy use by over 25%.

2. Automatic Slag Removal: Auto system with manual backup during power outages.

3. Production Automation: Integrates with PLC and conveyor for full automation.

4. Durable Mesh Chain Technology: German stainless steel mesh chains prevent thermal expansion breakage.

5. High-Quality Electrical Components: Imported from France/Japan for durability, low noise, reliability.

6. High-Capacity Tunnel Oven: Boosts production, efficiency, saves labor.

7. Precise Temperature and Speed Control: Independent heat controls; speed customizable for products like bread, cakes.

8. Optimized Heat Distribution: Solves uneven heating (sides hot, middle cold) in traditional ovens.Company IntroductionShanghai Jingyao Industrial Co., Ltd. located in Shanghai, China, specializes in manufacturing Baking Equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of food machinery with a history of more than thirty years specializing in producing high-effective as well as energy-saving machinery and equipment for such baked food as dorayaki,panckae,biscuits, cakes, bread, pizza, etc.We have standard management, systematic management, process management and workers work in order.We have won our reputation in the world for our strict quality guarantee system, powerful technical strength, scientific operation means and excellent after-sales services.F&Q1. Why buy from us instead of other suppliers?

We’re a Shanghai-based enterprise integrating R&D, production and trade, specialized in baked whole-set equipment (e.g.,

full-automatic lines for biscuits, cakes, Dorayaki)We have 8 R&D personnel, follow ISO9001 standards, own advanced production facilities, and our products are sold domestically and exported globally.2. Why choose us?

* Professional team: 8 R&D staff and international trading team ;

* Strict quality control: Implements ISO9001 system, pre-shipment testing with videos/photos ;

* Privacy protection: Values and safeguards customer privacy.3. What to consider when choosing machines?

* Site size: Match equipment dimensions (e.g., biscuit lines are 41.1-54.5m long) ;

* Product type: Select specialized lines (e.g., cake lines for cakes, cookie machines for cookies) ;

* Power & capacity: Confirm voltage (mostly 380V/50Hz), total power (e.g., oven power 35-60KW) and production capacity (e.g.,cake line 300-400kg/h) .4. What if temperature control malfunctions?

Our rotary ovens have reliable control systems and overheating safety mechanisms ; 24/7 after-sales team offers remote

troubleshooting or on-site repair.