Advanced Full-Automatic Cake Production Line for Sale-Y

Product Description

1. Our fully automatic cake line is developed by integrating advanced European equipment technology and tailoring to the specific conditions of each workshop. This integrated system combines electrical, optical and mechanical tech to ensure smooth, unified operation.

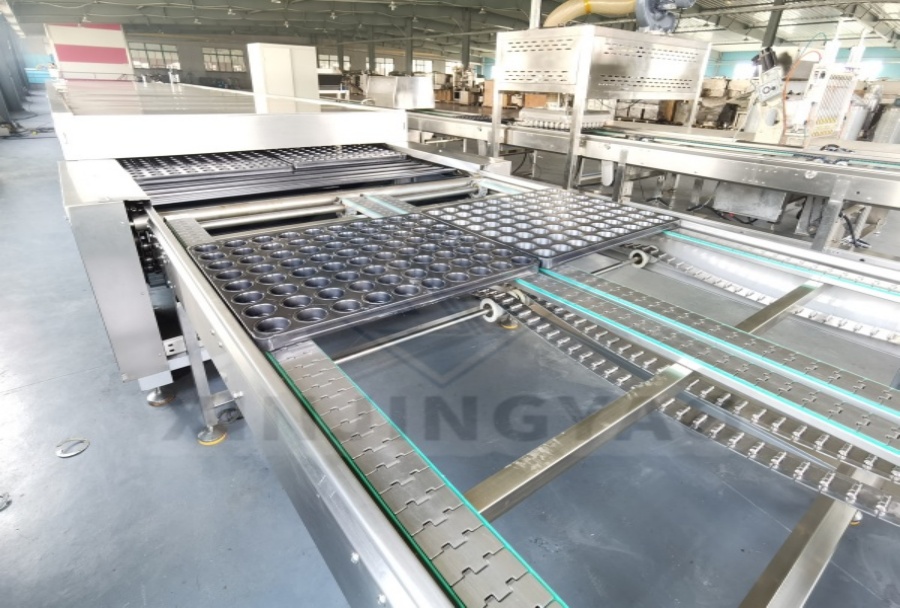

2. The system includes five main parts: a batter preparation module, baking gear, filling unit, cooling component and sterilization part. (These parts can also be assembled into semi-automatic configurations or high-yield lines.) Tunnel ovens offer multiple choices, such as electric, diesel, gas and thermal oil versions.

Application

1.This multi-use production line handles the whole manufacturing flow, from batter mixing right through to final packaging.

2.It covers all key processing procedures, like shaping, extrusion, baking, filling, rolling, cutting and sterilization.

3.When making various cake types, the line has great flexibility: simply swapping molds lets it make stuffed egg yolk pastries, paper cup cakes and sliced cakes in different designs.

4.The intelligent filling equipment has a detection function — no cake on the conveyor belt means the filling needle stops automatically. This not only stops material waste but also cuts down cleaning work.

Features

1.Controlled by a computerized frequency converter system, the production line enables precise parameter adjustment and simple operation. The tunnel oven is equipped with six temperature zones (covering front, middle, rear, upper and lower areas) and hot air circulation. These zones are regulated by proportional motors and butterfly valves to ensure uniform heat distribution, resulting in soft baked cakes with an even golden color.

2.Additionally, minimal manual product contact and the sterilization component extend the products’ shelf life while complying with food safety standards. Backed by tailored solutions and reliable after-sales service, this system is highly acclaimed in the bakery equipment market.

Advantage

Fast, even mixing of ingredients; consistent slurry texture. * Mace air infusion: Efficient aeration for stable rise; delicate structure, great taste. * Food-grade stainless steel: Safe, durable, corrosion-resistant, easy to clean. * Touch screen: Easy operation, precise control; stores recipes for versatility. * Labor-saving: Single-operator use; streamlined mixing-to-feeding process.

Detail Display

.jpg)

.jpg)

.png)