-

16 trays rotary oven electric gas diesel heating baking oven hot air rotary oven for baking

Suitable for biscuits, shortbread, pizza and roast chicken and duck baking

16 trays rotary oven is equipped with a rotating rack system that ensures even heat distribution, resulting in perfectly baked goods every time. With a spacious interior that can accommodate up to 16 trays at a time, this oven eliminates the need for constant monitoring and rotating of trays, allowing for a more efficient and streamlined baking operation.

-

sprial mixer with lifter, automatic discharge for bread industrial bread dough mixer planetary dough mixer

Our spiral mixer dough mixer is equipped with a powerful lifting mechanism that eliminates heavy lifting work, allowing operators to handle large amounts of dough more easily and safely. The lift effortlessly raises and lowers the mixing bowl, seamlessly transferring dough from the mixer to the next stage of the baking process. This advanced feature not only saves time and labor, but also ensures a consistent, high-quality product every time.

-

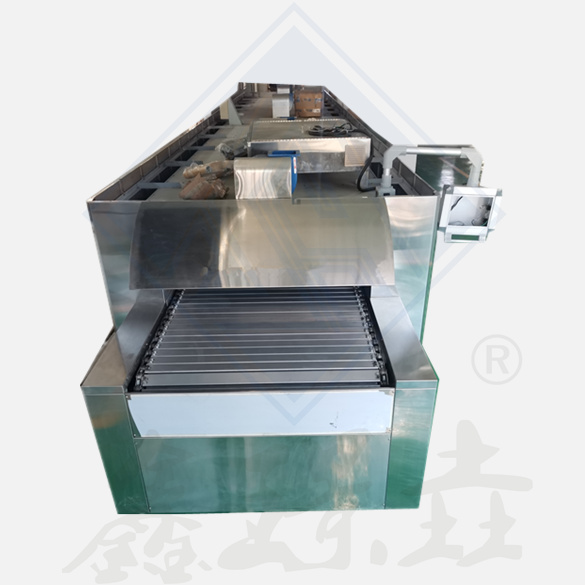

Tunnel oven conveyor oven electric food industrial naan tunnel oven for pita bread

The tunnel oven is a highly versatile and customizable oven that offers a wide range of advantages for your production line. One of the main advantages of this type of oven is the ability to customize it to meet specific production needs. This means that dimensions, tunnel length and conveyor speed can be easily adjusted during the design phase to suit any cooking requirements and type. Whether you need to bake small batches of delicate pastries or large quantities of hardy bread, our tunnel ovens can be customized to your exact specifications.

-

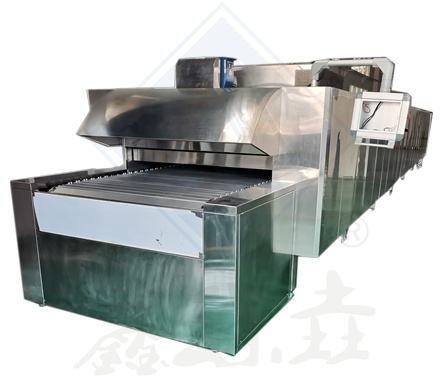

10 meters tunnel oven commercial baking oven tunnel electric oven for baking cookies

The tunnel oven is a versatile and reliable piece of equipment that can handle a variety of products including bread, pastries, pizza and more. With its advanced design and technology, this oven ensures consistent baking results every time. The spacious interior allows for high-capacity production, making it ideal for high-demand businesse

-

600kg/h Full Automatic Hard soft Candy Production Line

What kind of candies can we produce with a full automatic candy production line?

Well, the possibilities are endless! With the latest technology and advanced machinery, a full automatic candy production line can produce a wide variety of candies, including double colors candies, single color candies, multicolor candies and different shapes.

The production line is equipped with PLC control to handle candy vacuum cooking, conveying, and depositing procedures. This ensures precise and efficient production, resulting in high-quality candies every time. Additionally, the line is capable of performing rationed filling of essence, pigment, and acid solutions, allowing for the creation of unique and flavorful candies.

One of the standout features of the machine is its automatic stick placing device, which provides good stability and reliability. This ensures that each candy is perfectly formed and ready for packaging. Furthermore, the entire production line is designed with sanitation in mind, featuring a compact structure and reliable performance. This not only ensures the quality and safety of the candies but also makes for easy cleaning and maintenance.

With this level of technology and precision, the production line can create an array of candies, including double colors candies, which feature two distinct colors in a single piece. Single color candies are also easily produced, providing a classic and timeless treat. And for those looking for a more visually striking option, the production line can also produce multicolor candies, featuring a rainbow of hues in each piece.

In conclusion, a full automatic candy production line offers the capability to produce a wide range of candies, from classic single color options to more unique double and multicolor varieties and multi-shapes candies. With its advanced technology and efficient production capabilities, the possibilities for candy creation are virtually limitless. So, whether you’re craving a traditional treat or a more innovative confection, rest assured that a full automatic candy production line has you covered.

-

450kg/h 3D flat lollipop full automatic candy production line

Shanghai Jingyao Industrial Co., Ltd., we understand the importance of efficiency in confectionary production. That’s why our hard candy makers can dose and mix ingredients such as flavors, colors and acid solutions in one streamlined process. This saves time and energy, increasing productivity. With our machines, you can rest assured that your candy releases will be flawless. Conveyor chain, cooling system, and double demoulding devices cooperate seamlessly to ensure consistent and smooth demoulding of various shapes of candies. Whether you want round candies, heart-shaped candies, or any other custom shape, our machines have you covered. As a leading manufacturer in the food machinery industry, Shanghai Jingyao Industrial Co., Ltd. prides itself on providing high-quality machinery to increase productivity and efficiency in the food production process. With years of experience and expertise, we have become a trusted name in the industry. Our hard candy making machines are just one part of our commitment to provide our customers with cutting edge technology and reliable performance. Choose our hard candy making machines and experience the difference in candy production. Contact us today to learn more about this innovative machine and how it can revolutionize your confectionery process.

-

300kg/h Jelly candy manufecturing two lines candy molds production line

Shanghai Jingyao Industrial Co., Ltd. is located at Shanghai, China. Specialized in manufacturing Candy making equipment. We have our own R&D department and professional manufacturing base.

Our enterprise is a professional manufacturer of Candy making equipment with a history of more than thirty years specialized in producing machinery and equipment for such (semi)automatic hard/soft candy production line ect.

We have won our reputation with our strict quality guarantee system,powerful technical strength,scientific operation means and excellent after-sales services.

Main products of food machinery:Control Candy Depositing Machine, Sugar cooking pot,Candy Cooling Tunnel etc.

-

100-150kg/h Full automatic Jelly Gummy candy hard candy production line

Full automatic candy production line to make different kind of candies:

The full automatic candy production line is a state-of-the-art production equipment designed to cater to the various demands of the candy industry. This advanced machinery is capable of producing a wide range of candies including soft gummy candy, hard candy, 3D lollipops and more. It is an indispensable tool for candy manufacturers looking to streamline their production process and meet the ever-growing demand for diverse candy products.

The production line is a kind of production equipment researched and developed for producing gel soft candies according to the special production requirements of gummy candies. It can continuously produce various forms of pectin or gelatin-based soft candies, allowing for an extensive range of flavors, shapes, and sizes to be created with ease. Additionally, the machine can also produce depositing soft lollipop candies after the replacement of molds, providing even more versatility in candy production.

One of the key advantages of this full automatic candy production line is its high degree of automation. Through high automatic production, it can produce products of stable quality, save manpower and space, and reduce production costs. The efficiency and reliability of the machinery make it an essential asset for large-scale candy production.

Moreover, the production line is built with precision engineering and utilizes advanced technologies to ensure that the candies produced are of the highest quality. Whether it’s the perfect texture of soft gummy candies or the intricate design of 3D lollipops, this full automatic candy production line is designed to meet the exacting standards of the candy industry.

-

Ice block making machine 5 tons 10 tons 15 tons 20 tons

Block ice machines, also known as industrial ice makers, are designed to produce large blocks of ice for commercial and industrial use. These machines are capable of creating solid, uniform blocks of ice that can be used for applications such as seafood preservation, concrete cooling, and commercial refrigeration.

Some key features and options to consider when choosing a block ice machine include:

- Production Capacity: Block ice machines are available in a range of production capacities, from smaller units suitable for restaurants and small-scale operations to larger machines capable of producing high volumes of ice for industrial use.

- Block Size Options: Depending on the specific application, block ice machines may offer various block size options to accommodate different requirements.

- Automatic Operation: Some block ice machines feature automatic ice harvesting and storage, making the ice production process more efficient and less labor-intensive.

- Energy Efficiency: Look for block ice machines that are designed with energy-efficient features to help reduce operating costs and environmental impact.

- Durability and Construction: Consider machines constructed with high-quality materials such as stainless steel for durability, hygiene, and resistance to corrosion.

- Additional Features: Some block ice machines may offer features such as digital controls, remote monitoring and diagnostics, and customized options to meet specific business needs.

-

Ice block making machine industrial 1 ton 2 tons 3 tons

Block ice machines are designed to produce large, solid blocks of ice, typically used in industrial and commercial applications such as seafood preservation, concrete cooling, and ice sculpture carving.

These machines are capable of producing ice blocks of various sizes and can offer features such as stainless steel construction for hygiene and durability, energy-efficient operation, and advanced control systems for optimal performance.

Block ice machines are available in different capacities depending on the amount of ice needed, and they can be either stationary or containerized for easier installation and transportation.

-

Automatic ice cube making machine 908 kg 1088 kg

Cube ice machines are designed to produce uniform, clear, and hard ice cubes for various commercial uses. These machines are commonly used in restaurants, bars, hotels, and other food service establishments. Cube ice machines come in different capacities and sizes to meet the needs of different businesses.

Here are some popular types of cube ice machines:

- Modular Cube Ice Machines: These are large-capacity ice machines that are designed to be installed on or above other equipment such as ice bins or beverage dispensers. They are ideal for businesses that require a high volume of ice production.

- Undercounter Cube Ice Machines: These compact machines are designed to fit conveniently beneath counters or in tight spaces. They are suitable for small bars, cafes, and restaurants with limited space.

- Countertop Cube Ice Machines: These small, self-contained units are designed to sit on countertops, making them ideal for businesses with limited floor space or for use at events and small gatherings.

- Dispenser Cube Ice Machines: These machines not only produce ice cubes but also dispense them directly into drinkware, making them convenient for self-serve applications in convenience stores, cafeterias, and more.

- Air-Cooled and Water-Cooled Cube Ice Machines: Cube ice machines come in both air-cooled and water-cooled models. Air-cooled machines are typically more energy-efficient, while water-cooled machines are better suited for environments with high ambient temperatures or limited air circulation.

When choosing a cube ice machine, it’s important to consider factors such as ice production capacity, storage capacity, energy efficiency, space requirements, ease of maintenance, and the specific needs of the business or establishment.

-

Ice cube making machine wholesaler 454kg 544kg 636kg

Cube ice machines come in various types and designs to cater to the diverse needs of businesses. Here are some popular types of cube ice machines:

- Modular Cube Ice Machines: These are large-capacity ice machines that are designed to be installed on or above other equipment such as ice bins or beverage dispensers. They are ideal for businesses that require a high volume of ice production.

- Undercounter Cube Ice Machines: These compact machines are designed to fit conveniently beneath counters or in tight spaces. They are suitable for small bars, cafes, and restaurants with limited space.

- Countertop Cube Ice Machines: These small, self-contained units are designed to sit on countertops, making them ideal for businesses with limited floor space or for use at events and small gatherings.

- Dispenser Cube Ice Machines: These machines not only produce ice cubes but also dispense them directly into drinkware, making them convenient for self-serve applications in convenience stores, cafeterias, and more.

- Air-Cooled and Water-Cooled Cube Ice Machines: Cube ice machines come in both air-cooled and water-cooled models. Air-cooled machines are typically more energy-efficient, while water-cooled machines are better suited for environments with high ambient temperatures or limited air circulation.